Warehouse Space Revolution: How Start-ups Are Challenging Traditional Models

You might think traditional warehousing is too intrenched to be disrupted, but a new wave of start-ups is proving that notion wrong.

As you seek the liberty to operate with agility and innovation, these newcomers are reshaping the landscape of logistics with on-demand warehousing solutions. They’re integrating robotics and automation to streamline operations, ensuring you’re not held back by outdated practises.

With data-driven inventory management, you gain unprecedented control over your stock, while micro-warehouse networks offer the flexibility you crave to expand or contract your storage needs swiftly.

And, for those of you who value sustainability, these start-ups are paving the way for greener warehousing that alines with your ethical standards.

Dive into the warehouse space revolution where freedom in logistics is not just a dream but a tangible reality.

Key Takeaways

- Start-ups are offering flexible and on-demand warehousing solutions, allowing businesses to scale their storage needs without long-term commitments.

- Robotics and automation integration in warehouses is streamlining operations, reducing labour costs, and enabling scalable growth potential.

- Data-driven inventory management, using real-time data collection and advanced predictive algorithms, is helping businesses optimise their inventory levels and reduce waste.

- Micro-warehouse networks and efficient distribution strategies, including strategic placement of storage facilities, are cutting down last-mile delivery times and empowering businesses to fulfil orders at unprecedented speed.

Disrupting With On-Demand Warehousing

You’ll find that start-ups are breaking new ground by offering on-demand warehousing, a flexible alternative to the fixed, long-term leases of traditional storage solutions. This shift isn’t merely a trend but a strategic manoeuvre within the shared economy, empowering businesses to scale storage needs fluidly. It’s a model that epitomises freedom, allowing you to adjust your space requirements in real-time without being shackled by long-term commitments.

Space optimisation is at the heart of this revolution. By leveraging underutilised warehouse space, these start-ups are maximising efficiency and offering you an innovative way to manage inventory. It’s a strategic approach that alines with just-in-time production methodologies, reducing waste and enhancing your ability to respond to market demands.

This analytical framework doesn’t just apply to start-ups; it’s a clarion call for established businesses to re-evaluate their storage strategies. You’re now in a position to dissect your warehousing costs and to pivot toward a more agile approach.

On-demand warehousing isn’t just a service; it’s a strategic tool that injects adaptability into your supply chain, positioning you to outmanoeuvre competitors who are still anchored to the old paradigm of fixed warehousing.

Robotics and Automation Integration

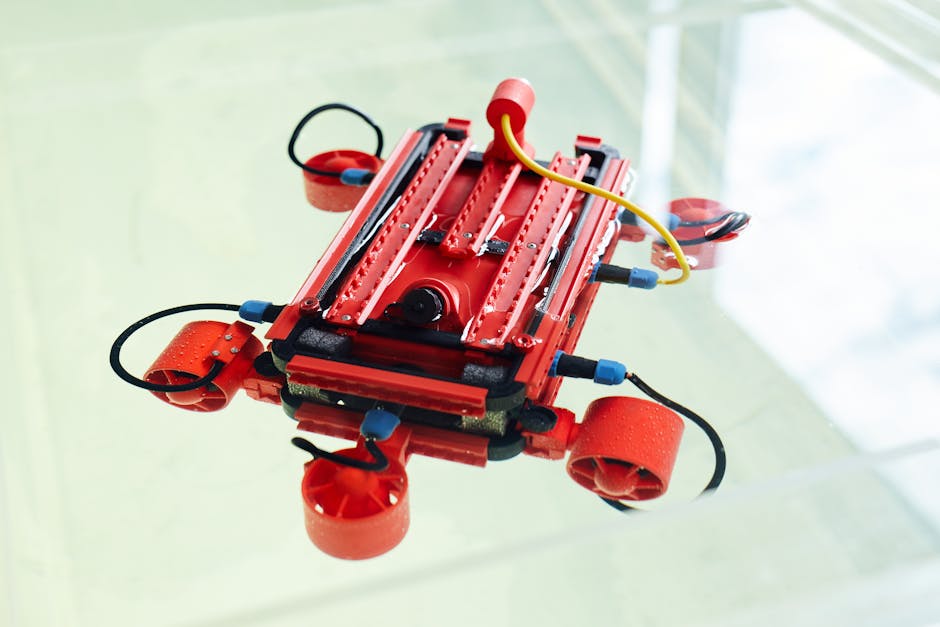

Amidst this shift towards on-demand warehousing, you’re also seeing a surge in robotics and automation integration that streamlines operations and slashes labour costs. As you explore the vast potential of these technologies, consider the strategic advantages they offer. Robotics don’t just perform repetitive tasks; they are now capable of smart packaging, ensuring products are wrapped and ready with precision and speed unheard of in traditional setups.

Predictive maintenance is another revolutionary aspect. By harnessing the power of data analytics, robots can predict equipment failures before they occur, minimising downtime and maintaining the relentless pace of innovation that you crave. This is freedom from the unpredictability of manual labour and equipment malfunctions—a liberation of your operational capabilities.

Here’s a snapshot of the revolution:

| Automation Aspect | Benefit | Strategic Impact |

|---|---|---|

| Smart Packaging | Enhanced accuracy | Efficient resource utilisation |

| Predictive Maintenance | Reduced downtime | Proactive operational optimisation |

| Robotics Integration | Labour cost reduction | Scalable growth potential |

In this new era, you’re not just a spectator; you’re a strategic architect, building a warehouse that’s not only responsive but ahead of the curve. Embrace this change, and watch your warehousing operations transform into a nimble, cost-effective powerhouse.

Data-Driven Inventory Management

Harnessing every byte of data, your inventory management becomes not just reactive but predictive, adapting to demand with remarkable agility. By employing sophisticated inventory prediction algorithms, you’re no longer at the mercy of guesswork. Instead, stock analytics become your compass, guiding each strategic decision towards optimal stock levels, reduced waste, and increased customer satisfaction.

Consider these pivotal elements:

- Real-time data collection: Sensors and IoT devices capture every nuance of stock movement, feeding into a central analysis hub.

- Advanced predictive algorithms: Machine learning models process historical and real-time data to forecast future demand with precision.

- Strategic restocking: Leveraging predictions to plan restocking schedules, ensuring you’re never overstocked or underprepared.

- Dynamic pricing strategies: Adapting pricing based on inventory levels and predictive trends to maximise revenue while maintaining customer loyalty.

In this landscape, you’re not just playing catch-up with market trends; you’re setting the pace. Your warehouse becomes a stronghold of efficiency, where each item is there for a reason and ready to move at a moment’s notice. The freedom to act on data-driven insights rather than gut feelings liberates you from the constraints of traditional inventory management, paving the way for a more resilient and responsive business model.

Micro-Warehouse Networks

Start-ups are transforming logistics with micro-warehouse networks that streamline distribution by situating storage closer to end consumers. This innovative approach is redefining urban logistics, making it more efficient and responsive. You’re no longer bound by the constraints of traditional large-scale warehousing. Instead, these nimble networks offer flexible storage solutions that adapt to fluctuating inventory levels, allowing for strategic positioning of goods.

The key to this revolution lies in the strategic placement of micro-warehouses within urban centres. This not only cuts down last-mile delivery times but also reduces shipping costs significantly. You’re empowered with the ability to fulfil orders at an unprecedented speed, which is crucial in today’s instant-gratification economy.

These start-ups aren’t just offering space; they’re offering a competitive edge. As a business owner, you gain access to a distributed network that can scale up or down based on real-time demand, without the shackles of long-term leases or hefty capital investments. You’re free to focus on growth, knowing that your logistics backbone is as dynamic and adaptable as the market demands.

Embrace this strategic, liberating approach to warehousing and witness how micro-warehouse networks can elevate your business in the fast-paced, ever-evolving landscape of urban logistics.

Sustainable Warehousing Solutions

You’ll discover that several start-ups are offering sustainable warehousing solutions, designed to minimise environmental impact while maintaining efficiency. These innovative firms recognise your need for freedom—not just in operations, but in the ethical footprint of your business. They’re strategically integrating technology and design to transform storage spaces. Here’s how they’re doing it:

-

Green Retrofitting: Upgrading older facilities to meet current environmental standards, ensuring that your existing infrastructure isn’t left behind.

-

Energy-Efficient Design: Building new warehouses with sustainability at their core, from insulated walls to smart lighting systems, to reduce your carbon footprint and energy bills.

-

Renewable Energy Integration: Harnessing solar, wind, or geothermal power to run operations, setting you free from the constraints of traditional energy sources.

-

Recycling and Waste Reduction Systems: Implementing in-house recycling programmes and waste-to-energy initiatives, allowing for a circular economy within your logistics network.

Start-ups are strategically crafting these solutions to meet the demands of a market that’s increasingly conscious of its environmental responsibilities. By adopting these practises, you’re not just investing in the planet’s future—you’re also paving the way for a more resilient and adaptable business model.

Frequently Asked Questions

How Have Customer Expectations Influenced the Evolution of Warehouse Space Management in Recent Years?

You’ve seen how rising customer satisfaction demands have spurred better inventory accuracy, pushing you to adopt more strategic, innovative warehouse management to ensure the freedom of quick, reliable service they expect.

What Are the Potential Legal and Insurance Implications for Businesses Using Shared or On-Demand Warehousing Services?

You’re navigating a maze of regulatory compliance and contractual agreements, much like a tightrope walker. Balancing innovation with legalities, you’ll strategize to ensure freedom while minimising risks in shared warehousing services.

How Do Start-ups in the Warehousing Industry Secure Funding and Financial Support to Compete With Established Players?

You’ll find that start-ups tap into crowdfunding, venture capital, and angel investors, alining with current investment trends to devise strategic funding strategies, ensuring they’ve got the capital to innovate and disrupt the market.

What Are the Career Opportunities and Skill Requirements Emerging in the Warehousing Sector Due to These Innovative Changes?

You’re on the brink of a career goldmine with robotics integration and sustainable practises reshaping warehousing! Master these innovative skills strategically, and you’ll unlock unparallelled freedom in a rapidly evolving job landscape.

How Do These Warehouse Space Revolutions Impact the Global Supply Chain, Especially in Developing Countries?

You’ll find these changes streamline global supply chains, with inventory localisation fostering quicker distribution in developing countries, while sustainability practises promote strategic growth and innovation, granting greater freedom in market responsiveness.

Conclusion

As you navigate the ever-evolving landscape of logistics, remember the warehouse space revolution isn’t just about storing goods—it’s a strategic game-changer.

Embrace on-demand models, let automation and robots be your tireless allies, and let data-driven insights steer your inventory with precision.

Think small to go big with micro-warehouses, and tread lightly with green solutions.

It’s a brave new world in warehousing—be the trailblazer who masters it.

Contact us to discuss our services now!