The Future of Warehousing: Trends and Predictions for the Next Decade

Just as Prometheus bestowed fire upon humanity, igniting progress, the next decade in warehousing promises to unleash innovations that’ll redefine your freedom to operate efficiently.

You’re standing at the precipice of a revolution where automation and robotics aren’t just luxuries but essentials, streamlining your operations with precision.

Imagine your inventory managed by the Internet of Things (IoT), turning warehouses into nerve centres of information, optimising your space and time.

You’ll witness the rise of the smart warehouse, where data-driven decisions are the norm, not the exception.

Embracing sustainability, you’ll navigate the green logistics landscape, ensuring your footprint is as light as your workload.

And as the workforce evolves, you’ll have the opportunity to develop new skills, keeping you ahead in the game of efficiency and innovation.

Welcome to the future of warehousing—a realm where your quest for operational liberty meets the frontiers of technological advancement.

Key Takeaways

- Integration of automation and robotics is reshaping the warehousing industry, increasing efficiency and streamlining operations.

- The adoption of IoT technology in warehousing enables real-time tracking, accurate data-driven insights, and improved inventory management.

- Smart warehouses enhance efficiency and productivity through real-time inventory tracking, predictive maintenance, and autonomous guided vehicles.

- Warehouses are increasingly adopting sustainable practises and green logistics to reduce environmental impact and ensure operational efficiency.

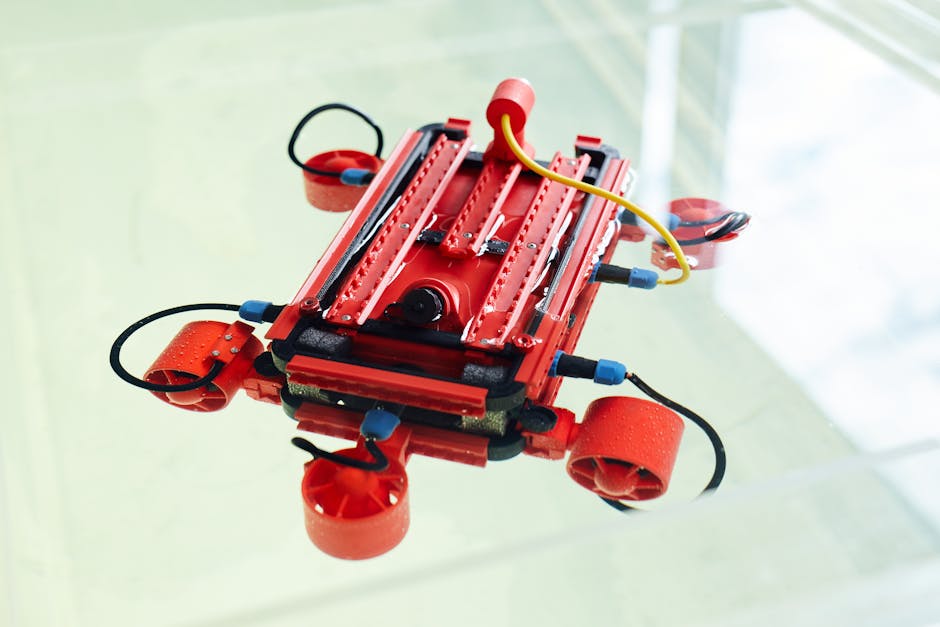

Automation and Robotics Domination

As you look to the future of warehousing, you’ll notice that the integration of automation and robotics is poised to become the dominant force reshaping the industry. The surge in robotic maintenance and human-robot collaboration isn’t just a fleeting trend; it’s the backbone of a revolution.

Data indicates a steep incline in the adoption of smart robotics, with the global warehouse automation market expected to reach $30 billion by 2026, growing at a CAGR of approximately 14% from 2021.

This shift is driven by the relentless pursuit of efficiency and the freedom from repetitive, labour-intensive tasks. Robotic systems are becoming more adept at ensuring uptime through predictive maintenance, which uses data analytics to pre-emptively service machinery before breakdowns occur. This not only cuts costs but also minimises downtime, ensuring a seamless flow of operations.

Meanwhile, human-robot collaboration is becoming more sophisticated, with robots designed to work alongside humans rather than replace them. These collaborative robots, or ‘cobots’, enhance human capabilities, allowing for a more liberated and strategic use of human skills. The interplay between human intuition and robotic precision creates a dynamic workspace that’s as innovative as it’s productive.

Integration of IoT and Warehousing

Harnessing the power of the Internet of Things (IoT) is transforming how you manage inventory, maintenance, and workflow in warehouses. With IoT, you’re not just streamlining processes; you’re catapulting into a realm where predictive maintenance becomes the norm, significantly reducing downtime and costs. Sensors on equipment continuously collect data, alerting you to potential breakdowns before they occur. This foresight allows you to schedule repairs during off-peak hours, ensuring that operations run smoothly.

Inventory accuracy is another arena where IoT shows its strength. Real-time tracking of goods through RFID tags and sensors means you’re always informed about stock levels and location. This precision minimises errors, cuts down on waste, and optimises warehouse space. You’re able to respond swiftly to supply chain demands, thanks to accurate, data-driven insights.

In this IoT-infused future, you have the freedom to manage warehouses with a level of efficiency and accuracy previously unattainable. As IoT technology evolves, you’re positioned to harness its full potential, yielding not just productivity gains but also a competitive edge in an increasingly fast-paced market.

Embrace this tech-driven approach, and you’ll find that your warehouse isn’t just a storage space—it’s a dynamic, interconnected hub of innovation.

Emergence of Smart Warehouses

You’ll witness a seamless transition from isolated tech upgrades to the emergence of fully integrated smart warehouses. This isn’t just a step forward; it’s a leap into a realm where efficiency, accuracy, and productivity are profoundly enhanced.

| Feature | Benefit | Technology Involved |

|---|---|---|

| Real-time Inventory Tracking | Reduces stock discrepancies | IoT, RFID |

| Predictive Maintenance | Minimises downtime | Machine Learning |

| Autonomous Guided Vehicles (AGVs) | Improves material handling | Robotics |

| Digital Twins | Enables virtual simulation | AI, Big Data |

| Augmented Reality (AR) | Streamlines pick-and-pack processes | AR Headsets |

Analysing the data, you’ll find that smart warehouses are no longer a distant dream. They’re here, transforming the logistics landscape. Digital Twins, creating virtual replicas of physical entities, are revolutionising warehouse planning and management. They allow you to simulate and optimise warehouse operations before implementing physical changes, thus granting you the freedom to experiment without risk.

Augmented Reality is reshaping training and operations. AR overlays digital information onto the real world, guiding workers through complex tasks with ease and precision. It’s a transformative tool that ensures you’re not just keeping up, but staying ahead. Embrace this change, and you’ll thrive in a future where the smart warehouse is the standard.

Sustainability and Green Logistics

Warehouses are increasingly adopting sustainable practises to reduce environmental impact and meet consumer expectations for green logistics. You’ll find that a significant trend is the integration of renewable energy solutions. Solar panels and wind turbines are being installed to power operations, significantly reducing carbon footprints. Data shows a surge in renewable energy adoption, with the Global Warehouse Market projected to increase its reliance on solar energy by a compound annual growth rate of around 25% from 2021 to 2025.

Delving deeper into sustainability, the circular economy is reshaping warehouse operations. You’re looking at a system where products, materials, and resources are kept in use for as long as possible, extracting the maximum value while in use, then recovered and regenerated at the end of each service life. This model not only reduces waste but also streamlines supply chains, offering you the freedom to operate within a regenerative loop.

As a stakeholder in the warehousing industry, you’re positioned to capitalise on these sustainable trends. By embracing green logistics, you’re not just complying with regulations or following a trend; you’re investing in a future where operational efficiency and environmental responsibility go hand in hand, ensuring your role in a market that increasingly values sustainability.

Workforce Evolution and Skill Development

As the warehousing sector embraces sustainability, skillset enhancement becomes crucial for your workforce to adeptly manage the advanced technologies and green systems shaping the future of logistics. The burgeoning gig economy has led to a more flexible labour market, but it also necessitates a workforce that’s agile and equipped with a versatile skill set. Data-driven analysis suggests that the following competencies are becoming increasingly valuable:

- Proficiency in operating sophisticated warehouse management systems (WMS)

- Expertise in robotics maintenance and troubleshooting

- Skills in data analytics to optimise inventory and supply chain efficiencies

- Knowledge in sustainable practises and energy-efficient technologies

- Familiarity with Augmented Reality (AR) for training and operational purposes

Embracing these skills won’t only make your team more adaptable but also more resilient to the rapidly changing demands of the industry. The integration of AR into training programmes, for example, can significantly reduce the learning curve for complex tasks, thereby enhancing operational freedom.

Meanwhile, the gig economy is redefining traditional employment models, promoting a culture where continuous learning and adaptability are key to staying competitive. As you invest in your team’s growth, you’re not just preparing them for the future; you’re empowering them to shape it.

Frequently Asked Questions

How Might Geopolitical Tensions Influence the Global Warehousing Landscape in the Next Decade?

Geopolitical tensions might push you towards supply diversification and localised stocking to mitigate risks, ensuring your stock’s freedom from single-source vulnerabilities and adapting to a shifting global warehousing landscape.

What Are the Potential Effects of Space Constraints in Urban Areas on Future Warehouse Design and Location?

You’ll see warehouses climbing skyward with urban verticalization and smaller, data-smart micro-fulfilment centres optimising limited space, ensuring your freedom to access goods swiftly, despite the squeeze of city landscapes.

How Could Changes in Consumer Privacy Expectations Impact the Warehousing Industry’s Data Collection and Analytics Practises?

As a fortress guards its treasures, you must protect consumer trust by upholding data ethics in your warehousing analytics. Any lax practises could erode this trust, impacting data-driven strategies and operational freedom.

Could the Rise of 3D Printing Technology Lead to a Decrease in the Need for Warehousing Space as More Products Are Manufactured On-Demand Closer to the Consumer?

You’ll likely see a shift towards customised production with 3D printing, leading to inventory decentralisation. This could reduce warehousing needs as on-demand manufacturing springs up closer to where you’re actually located.

In What Ways Might the Warehousing Industry Be Affected by Future Trade Agreements or Changes in International Trade Regulations?

Trade winds shift; if economic nationalism erects new trade barriers, you’ll see warehousing adapt, potentially becoming more localised to skirt hefty tariffs and changing regulations, ensuring the free flow of your goods.

Conclusion

As you navigate the nexus of next-gen warehouses, brace for a blend of bots and human brilliance. Your warehouse will become a whirring world where analytics and automation aline, sustainability isn’t just a slogan but a standard, and IoT infuses intelligence into every inch.

In this data-driven domain, upskilling is urgent, ensuring your workforce wields the wisdom to work alongside wondrous tech. Embrace this evolution earnestly, for it’s not just a trend but the transformation of tomorrow’s trade terrain.

Contact us to discuss our services now!